Yarn winders are special tools that are used for clothes and stuff out of fabric. They assist with preparing and sorting yarn — the long thread used to make textiles. There are many different models and sizes of yarn winders. Some are small enough to use in home projects and others are large enough for huge factories. However, yarn winders are an excellent sewing companion because they help you make all of that, along with fabric. Fabric creation becomes easy, quick, and efficient with the help of these tools. This piece will teach us how the XINDAWEI yarn winders aid in revolutionizing textile manufacturing and exactly why they are critical.

Yarn Winders: The Key To Production And Quality

Details of the sequential tasks are executed with high precision, and automated yarn winding is also possible at maximum yield with minimal yarn wastage. Using a yarn winder to wind yarn eliminates the tangles and knots that make working with yarn a hassle. That means the yarn is smoother and easier to work with. A smoother yarn translates into a nicer looking and nicer feeling finished product, which is very gratifying to customers. A key factor in customer retention is ensuring that they are satisfied with the quality of the fabric; the better you keep them, the more they will return to purchase further.

The Significance of Yarn Winders in Textile Manufacturing

Yarn winders get super helpful in making a ton of fabric at once. For large projects they can save a significant amount of time as they can perform the winding on its own. That means workers won’t have to spend hours winding yarn by hand. There are also fewer errors like broken yarn or knots that can arise from human-handled winding when it happens mechanically. This matters because errors can hinder production and lead to losses.

Klara Klepczarek | October 17, 2023

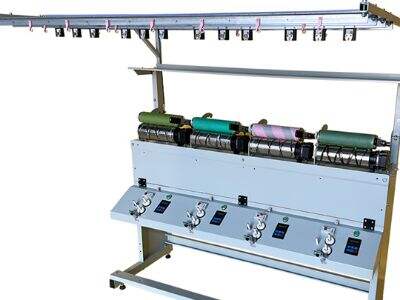

The XINDAWEI yarn winders are known to provide various amazing attributes that make their performance in the textile working process much smoother. Other models can process different types of yarn simultaneously, enabling faster and easier processing for workers. This way, if a factory makes various kinds of fabric, they can switch the yarns without losing time. Some models have special winding yarn patterns that allow them to work automatically. That allows you to wind several parts at the same time, with the correct tightness and smoothness, for even greater efficiency.

The Impact of Yarn Winders on Fabric Manufacturing

And this is where a yarn winder becomes an important tool for textile manufacturers. They help companies achieve their production objectives by producing quality yarn. During the smoothing process, from the yarn of good quality a better product is made so that the business can earn more money. Quality products ensure that customers are satisfied and will recommend the business to others. Using a best yarn winder on the other hand can reduce fatigue and prevent workers from being injured by doing the same task over and over. This allows workers to remain happy and healthy while carrying out their responsibilities.

How to Choose a Yarn Winder for Your Business

To sum up, if you are looking to improve better and efficiency in your textile production, XINDAWEI yarn winders is a good choice. These machines can increase your yarn output, enhance your products, save time, ensure employee comfort, and reduce errors. There is a wide variety of models to choose from, with unique features that will help you. Getting JD WINDER so that you can ensure your business more profitable and more high quality items you can make and your clients will appreciate. You will be very pleased with what you get when you choose XINDAWEI to meet your textile manufacturing needs, helping your business grow as a result!

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR MS

MS BE

BE KA

KA BN

BN KK

KK TG

TG UZ

UZ