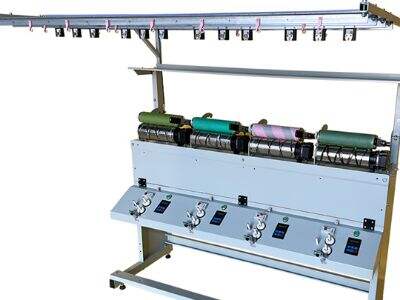

Maszyny do nawijania stożków: Tworzenie więcej z małego

W rzeczywistości, maszyny do nawijania stożków są tak samo niezbędne, jak pomocne podczas produkcji i efektywności nici. Pracownicy mogą nawijać dużą ilość nici w krótkim czasie za pomocą tych maszyn. Musieli najpierw wyprodukować nitkę, która wymaga przekształcenia w gotowe produkty. maszyna do skręcania bardziej efektywnie, co jest kluczowe w przemyśle odzieżowym. Nawijanie nici byłoby nużące i niezwykle czasochłonne, gdybyśmy tego nie robili, wyposażenie do skręcania drutu używając maszyn do nawijania stożków. To obniżyłoby tempo produkcji, co nie byłoby korzystne dla przemysłów, które zależą od produkcji i maszyna do skręcania drutów sprzedaży nici oraz innych produktów tekstylnych.

Maszyny do nawijania stożków wysokiej jakości nitki

Najlepsze produkcja nici dotyczy jakości. Konewki nie są najbardziej atrakcyjną częścią istniejącego procesu produkcji nici, ale odgrywają ogromną rolę w zapewnieniu, że nitka opuszczająca linię produkcyjną jest najwyższej jakości. Dzięki temu zapewniają, że nitka jest nakręcana jak najrówniej, co uniemożliwia powstanie węzłów i zacięć, które mogłyby utrudnić jej użycie w późniejszym etapie procesu produkcyjnego. Jeśli nakręcanie nitki zostanie wykonane niepoprawnie, może to prowadzić do defektów w produkcie końcowym. Lepsze nakręcanie przekłada się na lepszą nitkę, a to jest kluczowe dla produkcji wysokiej jakości produktów przeznaczonych dla klientów.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR MS

MS BE

BE KA

KA BN

BN KK

KK TG

TG UZ

UZ