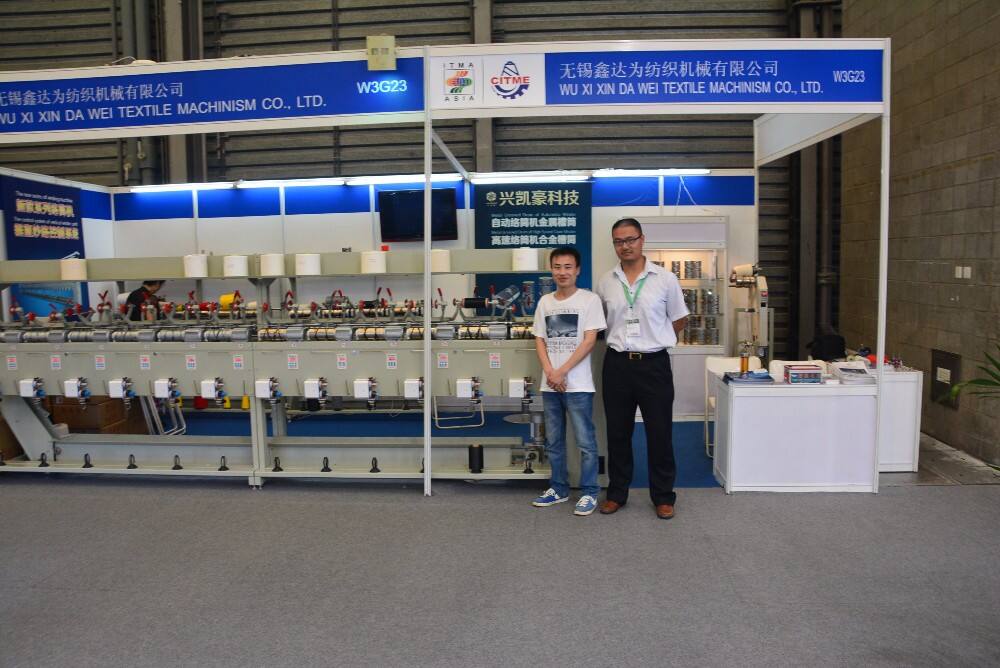

XINDAWEI

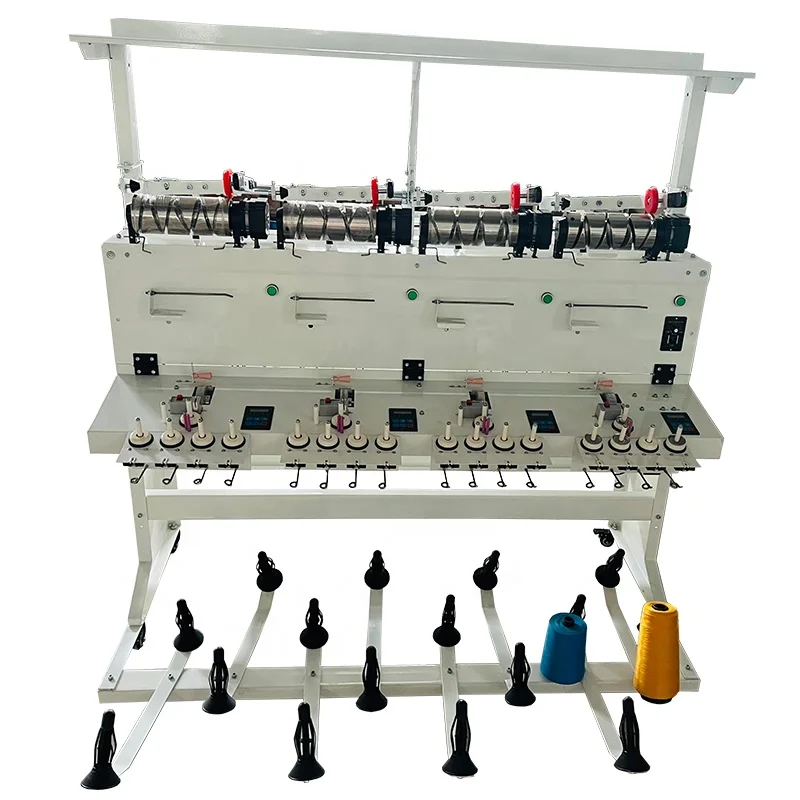

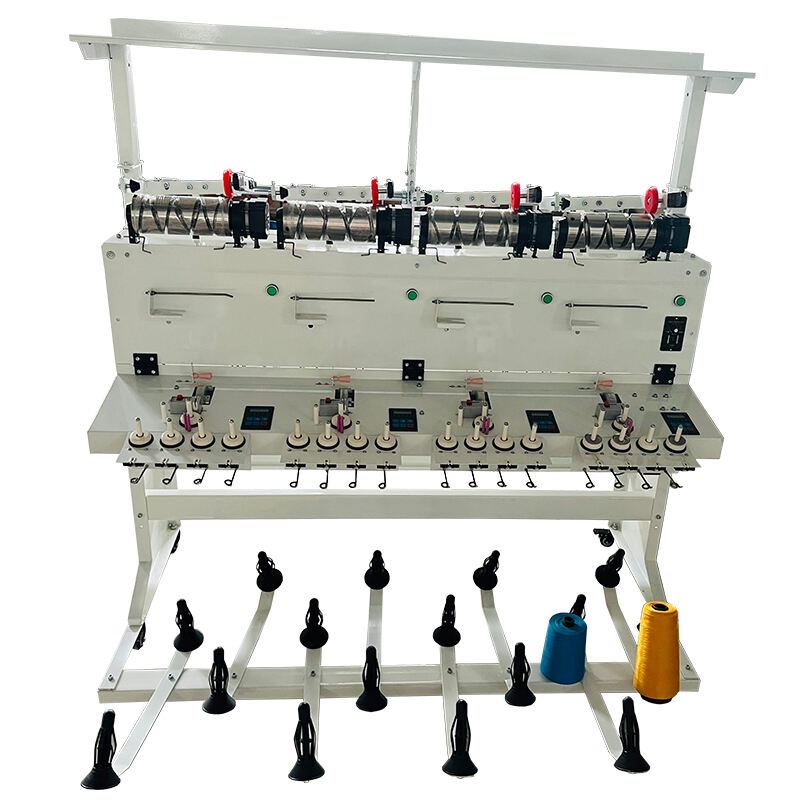

High Quality Doubling Winding High Speed Yarn Douling Winder Machine with Oiling Device supreme quality – the addition perfect any textile workshop, built increase production efficiency and enhance the quality of one's finished product.

Xindawei High Quality Doubling Winding High Speed Yarn Douling Winder Machine with Oiling Device a brand leading textile machinery, knows what's needed of modern textile manufacturers and it has created a winder machine that's not only fast efficient but additionally includes a very efficient oiling unit for improved yarn quality.

The unit is done with quality materials which can be highest and comes with a tight and robust design that permits for simple and quick procedure. Its design ergonomic additionally that operators can perhaps work in convenience for extended hours without tiredness.

This winder device has a variety wide of and functionality that makes it a must-have for businesses of all sizes. Considered one of its most innovative features is the yarn high-speed capability, to be able wind yarns faster and much more effortlessly. In addition, the oiling device ensures the yarn is lubricated to excellence, which enables uniformity and persistence on the board.

The unit additionally comes with a tension advanced system, which means that yarn tension may be simply modified to meet up the particular requirements of various forms of materials. Furthermore, a well-positioned display LED an intuitive easy-to-use interface that perhaps latest operators may use with simplicity.

The Xindawei High Quality Doubling Winding High Speed Yarn Douling Winder Machine with Oiling Device supreme quality Doubling Winding High Speed Yarn Douling Winder Machine with Oiling Device is likewise beautifully made with security in your mind. Different safety features happen integrated in the device ensure that the operator is obviously safe when making use of it.

The Xindawei quality good Winding High Speed Yarn Douling Winder Machine with Oiling Device is simple and easy regarding upkeep. This means that downtime significant by breakdowns maintenance dilemmas is minimized.

1. Automatic stop at preset diameter and at yarn break, speed up to 800 mt/min.

2. Special winder for the production of hard cones for dyeing and waxing, also can be equipped with oiling device, for any type of yarns & blends.

3. Slow start and progressive speed increase, adjustable winding tension with frequency aviator, mechanical clearers, yarn tensioners and anti-patterning device.

4. Supplied in sections of 1 up to 96 spindles ready for operation.

Item |

Technical parameters |

||||

Types of winding |

Drum, Random |

||||

Mechanical speed |

Up to 800m/min (process speed depending on quality of yarn and feed packages) |

||||

Package shape |

Cylindrical or conical |

||||

Traverse length |

10 inch: 250mm |

||||

Mechanical anti-patterning system |

Swing amplitude of creel :1-3mm |

||||

Package bobbin |

0°,3°30’ |

||||

Package diameter |

Up toφ 290 mm |

||||

Package density |

0.2-0.4g/cm3 |

||||

Fiber / count |

Cotton. flax, wool, silk, chemical fiber /Ne 6…180 |

||||

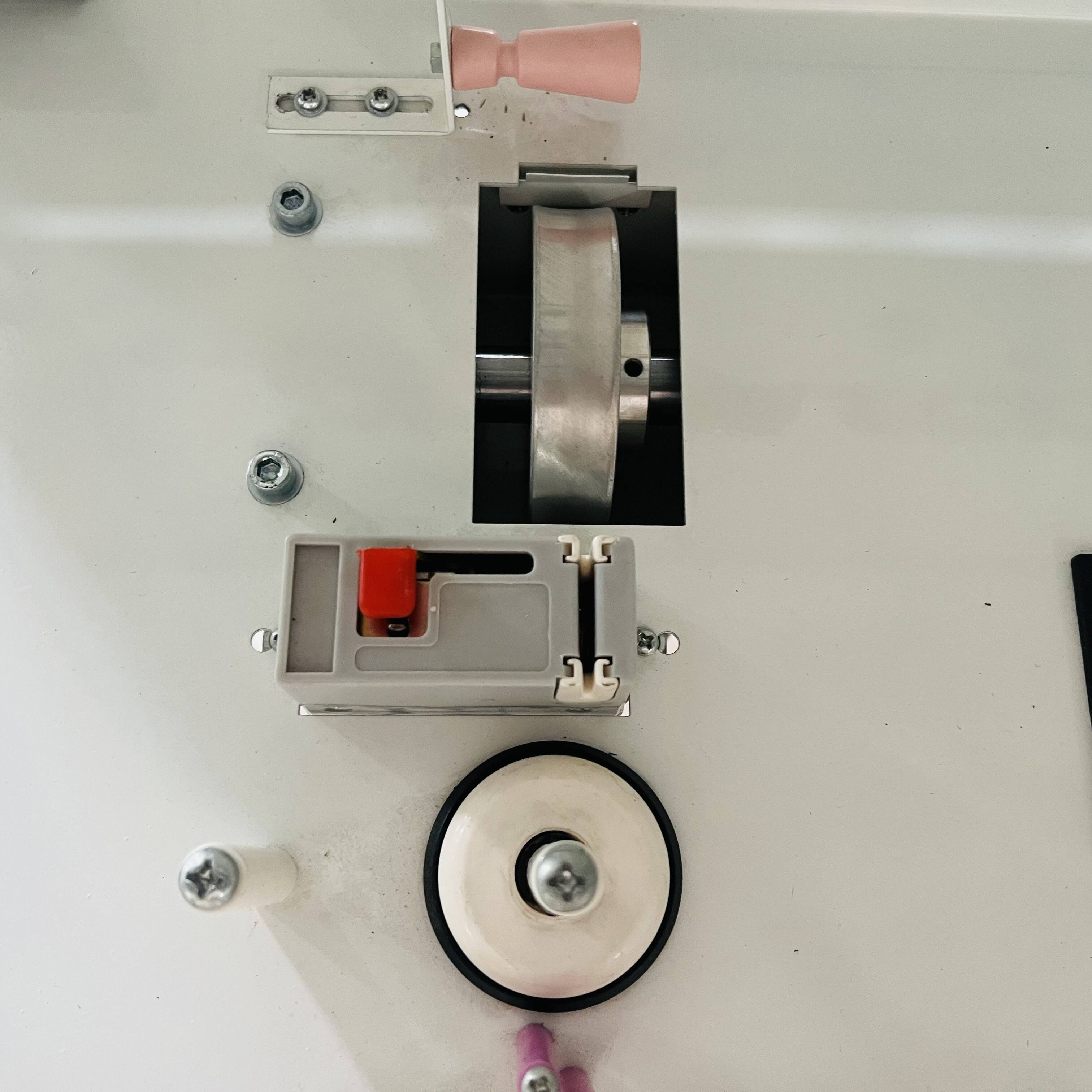

Auto stop while yarn break |

With electronic yarn detector, the spindle will stop when yarn break |

||||

Slow start |

For smooth start and better winding quality, supporting individual slow start for each spindle (available on request) |

||||

External dimensions |

1700 (length) ×700 (width) ×1.64(height) |

||||

Power supply |

220V |

||||

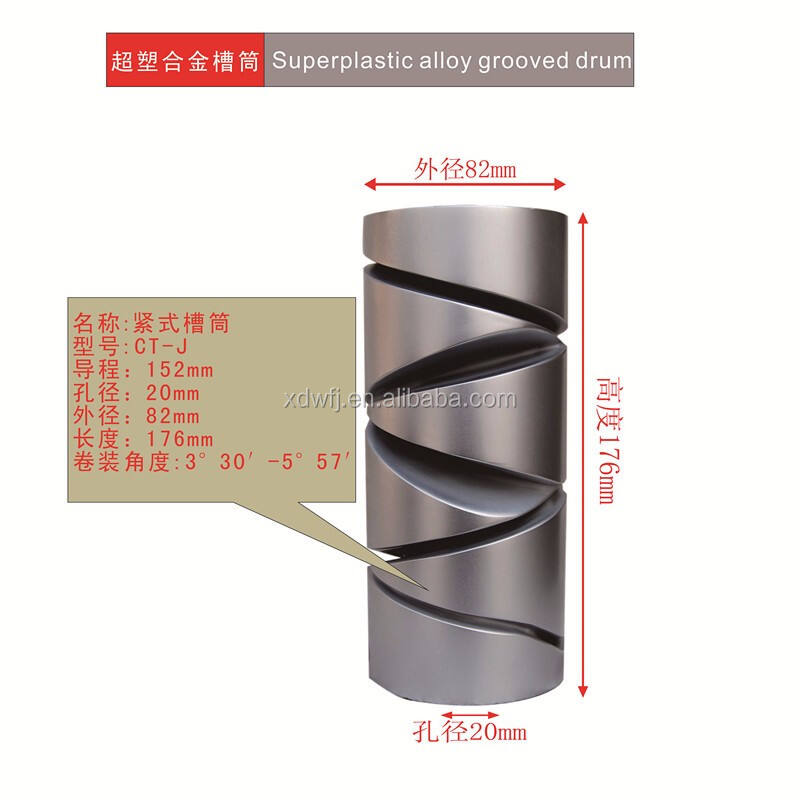

Super Plastic Winding Drum

Lead: 152mm

Outer diameter: 82mm

Length: 176mm

Turns: 2 .5

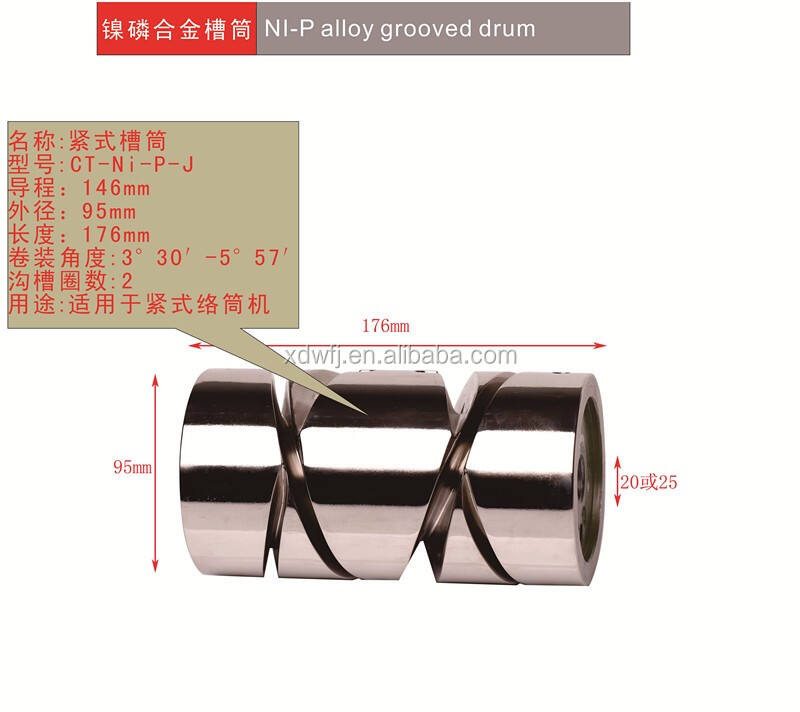

Ni-P Alloy Winding Drum

Lead: 146mm

Outer diameter: 95mm

Length: 176mm

Turns: 2

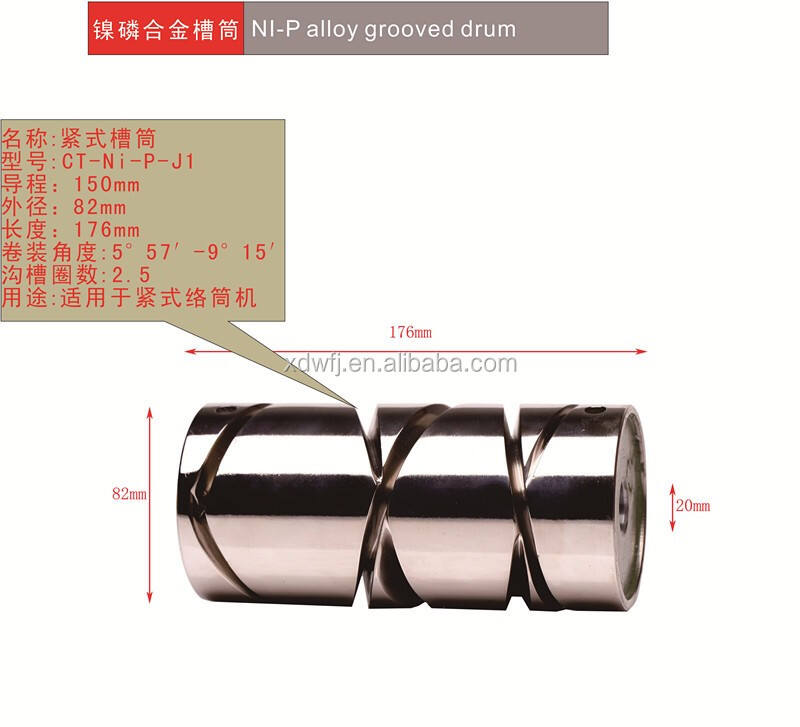

Ni-P Alloy Winding Drum

Lead: 150mm

Outer diameter: 82mm

Length: 176mm

Turns: 2.5