Цель XINDAWEI — производить лучшую нить для всех клиентов. Каждый день мы стремимся обеспечить высокий стандарт нашей нити. Мы стремимся к результату использования продукта, который превышает ожидания наших клиентов. Одним из способов достижения этого является использование машин, известных как конусные намотчики нити. Эти машины действительно помогают нам, так как они не только повышают качество нашей нити, но и способствуют снижению отходов в процессе.

Руководство по конусным намотчикам нити Преимущества конусных намотчиков нити

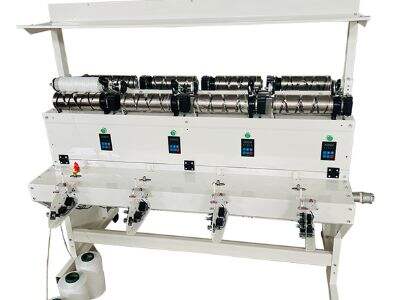

Конусные намотчики нити являются специализированными машинка для намотки шерсти устройствами, которые снимают нить с маленьких катушек или бобин и наматывают её на большие конусы. Существует несколько причин, почему этот процесс является важным. Во-первых, это позволяет упаковывать нить таким образом, что её легко транспортировать и хранить. Вместо множества маленьких катушек у вас есть большие конусы, которые содержат больше нити. Таким образом вы экономите место, и всё становится более организованным.

Преимущество использования большего количества намотчиков конусной нити заключается в том, что мы можем стандартизировать качество нити. Когда мы наматываем нить на большие конусы, мы можем регулировать, насколько туго наматывается нить и с какой скоростью она проходит через машину. Такой уровень контроля обеспечивает более высокое качество продукции с меньшим количеством ошибок и дефектов. Из-за этого мы также уменьшим количество отходов, образующихся при прокручивании этого процесса; следовательно, это более устойчивый метод.

Почему это важно: Конусные намотчики нитей для потрясающей нити

XINDAWEI, мы твердо верим, что высококачественная нить является наиболее подходящей для клиентов. И именно поэтому мы используем конусные намотчики нитей в нашем производственном процессе! Без этих машин было бы чрезвычайно сложно — если не совсем невозможно — создавать нить, соответствующую нашим строгим требованиям к качеству.

Сматывающие устройства для конусов позволяют нам обеспечивать стабильность и качество, которых ожидают и заслуживают наши клиенты. Контроль натяжения и скорости при намотке нити на конусы гарантирует отсутствие дефектов и недостатков, которые могли бы повлиять на конечный продукт. Это приводит к улучшению качества нитей, с большей стабильностью, что делает их проще в использовании нашими клиентами в своих проектах.

Как работают сматывающие устройства для конусов, чтобы способствовать производству пряжи

Сматывающие устройства для конусов не только улучшают качество нашей пряжи, но и играют важную роль в процессе прядения. После прядения нить протягивается через ряд валков и наматывается на меньшие бобины или катушки. Тем не менее, эти маленькие упаковки могут создавать проблемы с контролем натяжения и скорости нити.

Для обеспечения более строгого контроля процесса прядения мы навиваем нить на большие конусы с помощью конусных намотчиков. Это даёт им контроль, что приводит к лучшему и более точному продукту. Также это позволяет нам использовать более длинные отрезки нити, что увеличивает общую производительность. Чем больше нити мы можем прядать за меньшее время, тем лучше для нашего бизнеса и наших клиентов.

Конусные намотчики нити и их влияние на качество нити

Что касается определения с использованием конуса автоматических намотчиков пряжи , качество нити, производимой в XINDAWEI, во многом определяется использованием конусных намотчиков. Обучаем персонал до октября 2023 года. Наши клиенты получают нить, которая является прочнее и надёжнее для их задач.

Кроме того, намотка конусов позволяет нам работать с более длинными отрезками нити, что помогает избежать множества узлов в конечном продукте. Чем меньше узлов, тем выше сопротивление перетягиванию, ломке или разрыву при использовании. Это повышает качество пряжи в целом и дает нашим клиентам уверенность в покупке пряжи у нас.

Максимизация пряжи и минимизация отходов с помощью намотчиков пряжи на конусы

Намотчики пряжи на конусы также очень ценны для всех, кто следит за выходом продукции и отходами. Нередко часть пряжи просто отклоняется или выбрасывается из-за дефектов или нерегулярностей в процессе обработки волокна. Это раздражает как нас, так и окружающую среду.

Мы будем наматывать пряжу на большие конусы, используя намотчика конусов ниток чтобы более эффективно использовать производимую нами пряжу. Все это позволяет нам максимально использовать каждую партию пряжи, которую мы производим. Это не только помогает окружающей среде, но и позволяет нашему бизнесу сократить отходы прядения благодаря использованию намотчиков пряжи на конусы.

В заключение

Дата: {{date}} Октябрь 2023 В XINDAWEI мы отслеживаем данные и производственный процесс до достижения идеального результата. Мы предлагаем нашим клиентам качественный продукт нитей. Одним из ключевых способов, какими мы этого добиваемся, является использование намоточных машин для конусных нитей. Эти машины необходимы для повышения качества и последовательности наших нитей, для максимизации выхода продукции и снижения отходов. Мы используем намоточные машины для конусных нитей в производстве, которым клиенты могут доверять и которые приятны в использовании в своих проектах для зрителя. 2023.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR MS

MS BE

BE KA

KA BN

BN KK

KK TG

TG UZ

UZ