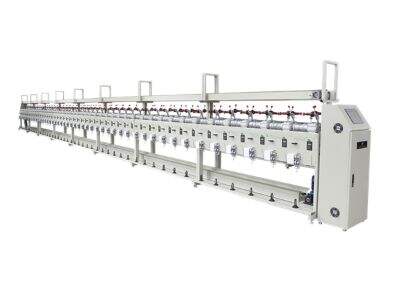

A lot of companies, including XINDAWEI, realize that the right yarn winder can help them produce much more yarn while wasting less material. On this guide, we are gonna help you identify which is the best yarn winder to generate a beautiful yarn. Some helpful tips will be shared that can help make everything run smoother and even more efficient.

How to Select the Right Yarn Winder

The selection of the yarn winder plays a major role to get the quality yarns quickly and easily. Below are a few vital considerations to keep in mind while choosing a yarn winder:

Type of yarn – Different yarns require different winding methods. For example, soft and delicate yarns like silk need to be wound carefully so that they don’t get squished or torn. For thicker yarns such as wool, the holder must be more sturdy to be able to support the added weight. Matching the winder to the type of yarn is essential.

Production capacity – Depending on the type of winder you select, the amount of yarn that can be produced will differ daily. Depending on how well you choose a winder, you could be waiting a while to get your yarn. Choose a Spare Parts For Yarn Winderthat works out for your production and that minimize the unemployed time.

Cost – A yarn winder can vary in cost depending on its features as well as specifications. While it’s vital to select a winder within your price range, don’t be afraid to pay the right amount and never settle for cheap. All that said, you want a well functioning winder that will assist you in producing quality yarn.

More Tips for Producing More Yarn and Less Waste

Once you’ve selected the perfect yarn winder for your personal needs, there are still more things you can do to produce even more yarn and help create less waste. Here are some great tips:

Adjust settings - Yarn winders typically have adjustable settings to dictate the speed of the winding process, the winding tension and, in some cases, the thickness of the yarn itself. Make sure to adjust the right yarn controls for the type of yarn that you are using. That way you avoid hassles like tangles, knots, and breaks, which can slow you down and waste yarn.

Don't take it lightly - Winding yarn is a fragile process that needs close attention. Whenever you are using the yarn and the winder, you will need to treat everything a little delicately. This will help avoid any snags or tangling which may occur if you aren’t mindful. Just remember to take your time, the more careful you are the better your yarn

Optimize the workflow The workflow is the work needed to prepare the yarn for winding, the act of winding, and finally the packing of the finished yarn. This process needs to be as seamless as possible. Just keep looking for things to fix around you, to automate, so that you will spend less time waiting, and everything will go smoothly. It requires planning in advance and rearranging your environment so you can work more effectively.

The Right Winding Equipment Is Key

In order to spin yarn well, you have to have the correct tools and equipment. So here’s why you need the right winding equipment:

Consistency – Using appropriate winding tools, it ensures that the cone winder yarn is always the same thickness and structure, ensuring accuracy. Having a consistent yarn is very important because it affects the quality and durability of the end product. Non-uniformity in the yarn can cause issues in the subsequent stages of the garments being made.

Increased production Turn a good quality yarn winder ensures that high quality yarns are produced quickly and efficiently. Less wait time, more yarn, everybody wins, especially when it comes to fulfilling customer demands and deadlines.

Reduces waste – A good yarn winder can help reduce waste. A good winder decreases the waste of yarns made during the winding process. Not only is this better for the planet, it saves money too.

Advantages of Using Appropriate Winder

There are a lot of benefits to using the right yarn textile winder let’s look at some of them:

The right quality winder saves you production time. Doing so makes it easier for you to meet client demands and deadlines. When you make yarn faster, your customers will be happier.

Saves dough — A good winder cuts the amount of waste it produces, saving you money on what goes into creating defective or unusable yarns. This is really important for successful businesses.

Improves production efficiency – A good winder delivers efficient production flow. It results in higher productivity and effectiveness rates in the yarn manufacturing process. Yarn production is determined by your winder; the better it is, the more you can make.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR MS

MS BE

BE KA

KA BN

BN KK

KK TG

TG UZ

UZ